Even though you'd never know it was now winter from the weather, it's still one of our favorite times of the year. The crew toils tirelessly day in and day out, and this group certainly deserves some rest and a hearty meal.

We appreciate the privilege of being able to enjoy the beauty of Laurel Creek each and every day.

However, at this time of the year we are especially thankful to all who make this possible. From a great group of dedicated employees we get to work with, to the many members who give their time to enhance Laurel Creek now and for the future, we wish you Happy Holidays and a wonderful 2016!

Sunday, December 27, 2015

Monday, December 21, 2015

Buried Treasure

While we may not have found anything we could use to pay off holiday shopping bills, the rental of a metal detector last week did help locate several irrigation quick coupler valves, many of which had been buried for the past 25 years.

Without an "as-built" or drawing of record for the golf course irrigation system, locating valves can be difficult. For some holes, we have the irrigation contractor's field notes, which can be helpful, but aren't drawn to scale, and often are like trying to decipher hieroglyphics.

The quick coupler valves we located are what we connect to for handwatering with a hose. When originally installed, no valve boxes were placed around these, so many were soon grown over. Other isolation valves on the golf course only had a 4" sleeve of PVC and 4" cap over them. Trying to find a 4" lid in the Fescue is truly like trying to find a needle in a haystack.

In an effort to make all irrigation components easier to find, we have standardized on using 10" round valve boxes. When you know the general idea of a valve's location, this dramatically increases the odds of finding it, as a 10" round lid has close to 3X the surface area of a 6" lid, and more than 6X the area of a 4" lid.

One of the projects we'll be tackling this winter is the installation of 60 additional quick coupler valves, primarily for hand watering fairways. For both the new and old valves, we'll be sure to place them in valve boxes, so it's not the year 2040 when someone finds them again.

|

| The $15 to rent a metal detector was well worth it. |

Without an "as-built" or drawing of record for the golf course irrigation system, locating valves can be difficult. For some holes, we have the irrigation contractor's field notes, which can be helpful, but aren't drawn to scale, and often are like trying to decipher hieroglyphics.

The quick coupler valves we located are what we connect to for handwatering with a hose. When originally installed, no valve boxes were placed around these, so many were soon grown over. Other isolation valves on the golf course only had a 4" sleeve of PVC and 4" cap over them. Trying to find a 4" lid in the Fescue is truly like trying to find a needle in a haystack.

In an effort to make all irrigation components easier to find, we have standardized on using 10" round valve boxes. When you know the general idea of a valve's location, this dramatically increases the odds of finding it, as a 10" round lid has close to 3X the surface area of a 6" lid, and more than 6X the area of a 4" lid.

|

| This quick coupler valve sees the light of day for the first time in 25 years. |

One of the projects we'll be tackling this winter is the installation of 60 additional quick coupler valves, primarily for hand watering fairways. For both the new and old valves, we'll be sure to place them in valve boxes, so it's not the year 2040 when someone finds them again.

Sunday, December 13, 2015

Research that Helps in the Real World

This past week, turf managers from around the northeast attended the 40th New Jersey Green Expo. At events such as this, there are numerous opportunities to gain information from several different sources, including university turfgrass researchers.

One of the most interesting, and potentailly helpful presentations at this year's Expo involved management of the disease Anthracnose. For years Anthracnose has caused turf loss on putting greens, and researchers at Rutgers have spent over a decade looking for the solutions to this problem.

During this time, a set of best management practices have been established for reducing Anthracnose. However some of these recommendations often come at the expense of playability--green speed, in particular. This can leave turf managers feeling caught between two options, neither of which are appealing: Lean, fast greens, which are susceptible to Anthracnose, or slower greens, and unhappy golfers.

Having already told us how best to prevent Anthracnose, it would have been understandable if the team at Rutgers had gone no further in their study of the disease, feeling that their job was done. However, that hasn't been the case.

Realizing that some of the suggested best management practices for reducing Anthracnose may be at loggerheads with golfers' high expectations, the researchers have truly gone the extra mile in their efforts to provide us with practical, real world solutions.

The on-going research has now looked at different agronomic practices, such as topdressing, nitrogen fertility, and mowing height, to see how they all interact, both in terms of disease severity, and ball roll. The presentation given last week did an excellent job of showing the options for preventing Anthracnose while still maintaining acceptable green speed.

It's understandable if this puts many people to sleep. However, for those of us who live and love golf course turf, this is the kind of research that is invaluable in helping us create sound, science-based golf course management programs.

One of the most interesting, and potentailly helpful presentations at this year's Expo involved management of the disease Anthracnose. For years Anthracnose has caused turf loss on putting greens, and researchers at Rutgers have spent over a decade looking for the solutions to this problem.

During this time, a set of best management practices have been established for reducing Anthracnose. However some of these recommendations often come at the expense of playability--green speed, in particular. This can leave turf managers feeling caught between two options, neither of which are appealing: Lean, fast greens, which are susceptible to Anthracnose, or slower greens, and unhappy golfers.

Having already told us how best to prevent Anthracnose, it would have been understandable if the team at Rutgers had gone no further in their study of the disease, feeling that their job was done. However, that hasn't been the case.

Realizing that some of the suggested best management practices for reducing Anthracnose may be at loggerheads with golfers' high expectations, the researchers have truly gone the extra mile in their efforts to provide us with practical, real world solutions.

The on-going research has now looked at different agronomic practices, such as topdressing, nitrogen fertility, and mowing height, to see how they all interact, both in terms of disease severity, and ball roll. The presentation given last week did an excellent job of showing the options for preventing Anthracnose while still maintaining acceptable green speed.

It's understandable if this puts many people to sleep. However, for those of us who live and love golf course turf, this is the kind of research that is invaluable in helping us create sound, science-based golf course management programs.

Saturday, December 5, 2015

Good team work leads to better bunkers

As we often say, you have to try to work with Mother Nature and not against her. So, given the dreary weather and saturated conditions earlier in the week, the tasks we could tackle were somewhat limited.

However, the crew was able to make great use of the time and bang out some bunker work. In a couple of days they got the bunkers nicely edged.

Given the limited play and growth during the winter months, this clean edge should last well into the spring, giving us a head start on 2016's to-do list.

However, the crew was able to make great use of the time and bang out some bunker work. In a couple of days they got the bunkers nicely edged.

|

| Mike uses the reciprocator to cut a new edge on #8's bunkers. |

Saturday, November 28, 2015

Winterization--the Golf Course and Beyond

Most people are aware that this is the time of year when we remove the water, or "blow out" the golf course irrigation system to avoid the chance of pipes freezing during the winter. However, the scale of this job may come as a surprise, as there are a number of other areas that must be winterized as well.

On the course itself, we have over 1,000 sprinklers, approximately 20 miles of 2" pipe, and another 5 miles of larger "main line" pipe, which ranges in size from 4" to 14" in diameter. We use a large compressor, rated at 750 or 825 cubic feet per minute to deliver the volume of air needed to get this job done expeditiously.

For the golf course sprinklers, we connect into a port at each of our two pumping stations. High volume is good, whereas high pressure is not. Remember that, generally speaking, air can be compressed, whereas liquids can not. With high pressure, the compressed air can expand quickly, breaking system components.

What you may not be aware of is that in addition to the golf course, there are several other locations on the property where water must be removed. On the Clubhouse grounds, this includes the bridge crossing pipe, the 32 zones of turf and landscape irrigation, the unheated Cabana building itself, and the four har-tru tennis courts.

But wait, we're still not finished. The entrance islands to the development also have irrigation systems which must be winterized. In fact, there are three separate irrigation controllers, meter pits, and backflow preventers for these areas.

It's a good feeling when we finally get this annual project completed. However, the success of this won't be known for months. Only when we charge the system next March will we find out if our efforts kept all pipes from freezing.

On the course itself, we have over 1,000 sprinklers, approximately 20 miles of 2" pipe, and another 5 miles of larger "main line" pipe, which ranges in size from 4" to 14" in diameter. We use a large compressor, rated at 750 or 825 cubic feet per minute to deliver the volume of air needed to get this job done expeditiously.

For the golf course sprinklers, we connect into a port at each of our two pumping stations. High volume is good, whereas high pressure is not. Remember that, generally speaking, air can be compressed, whereas liquids can not. With high pressure, the compressed air can expand quickly, breaking system components.

|

| A large compressor is required for purging water from the golf course. |

What you may not be aware of is that in addition to the golf course, there are several other locations on the property where water must be removed. On the Clubhouse grounds, this includes the bridge crossing pipe, the 32 zones of turf and landscape irrigation, the unheated Cabana building itself, and the four har-tru tennis courts.

|

| Water must be removed from the Cabana and tennis courts. |

But wait, we're still not finished. The entrance islands to the development also have irrigation systems which must be winterized. In fact, there are three separate irrigation controllers, meter pits, and backflow preventers for these areas.

It's a good feeling when we finally get this annual project completed. However, the success of this won't be known for months. Only when we charge the system next March will we find out if our efforts kept all pipes from freezing.

Saturday, November 21, 2015

I See the Light

Daylight Savings Time ended a few weeks ago, and for those of us who ready the course for play each day, this change was welcomed. With weekend play starting at 7:30 AM, the lack of light we experience in the fall can make things a bit sketchy for the first few greens we prep in the morning.

One of the things employees must do prior to cutting the green is to check for objects, such as stones and ball markers, which could damage the mower's reel. Even something as small as a twig or seed from a tree may spell trouble, as they can lodge in the grooved roller of the greensmower causing a scuff or line across the green. Of course, operators must also be mindful of how the mower's cutting; and, as with all motorized equipment, be certain that it's not leaking any fluids on the green.

While most of our greensmowers are equipped with lights, and employees often wear headlamps, it can still feel like a roll of the dice when we start in the dark, as it is very difficult to see and be aware of any of these issues on a green without full daylight to help.

Even with the shift to Standard Time it's not exactly bright out when we arrive now, however it's definitely a big improvement over those dark October mornings!

One of the things employees must do prior to cutting the green is to check for objects, such as stones and ball markers, which could damage the mower's reel. Even something as small as a twig or seed from a tree may spell trouble, as they can lodge in the grooved roller of the greensmower causing a scuff or line across the green. Of course, operators must also be mindful of how the mower's cutting; and, as with all motorized equipment, be certain that it's not leaking any fluids on the green.

While most of our greensmowers are equipped with lights, and employees often wear headlamps, it can still feel like a roll of the dice when we start in the dark, as it is very difficult to see and be aware of any of these issues on a green without full daylight to help.

In addition to the difficulty with greensmowing, other tasks, such as cup cutting can be challenging as well. An area of the green which appears to be a reasonable hole location in the dark may have an entirely different appearance once the Sun rises. Because of this, we often times will go out the day prior, and dot the hole locations we're going to be changing first the next day.

Even with the shift to Standard Time it's not exactly bright out when we arrive now, however it's definitely a big improvement over those dark October mornings!

Friday, November 13, 2015

A Shady Deal

Last week's USGA Green Section Record focused heavily on the impact of trees on a golf course. The northeast regional update noted:

The putting green by #1 tee has several issues, including its size and drainage problems. However, one of the greatest challenges this green faces is the growing environment. The picture below was taken on Monday, November 9, a full six weeks before the winter solstice:

With 2/3 to 3/4 of the green in the shade, you might think this picture was taken in early morning or late afternoon. The unfortunate truth is that it was taken at 12:30 PM. Last winter was tough on all of the grass, but we had only one green which actually suffered turf loss and had to be reseeded: The putting green.

- Sun angles change throughout the year. With the winter solstice a little more than a month away, take note of trees that are now shading your turf. Fall sunlight is critical to the hardening process and some trees weren’t causing shade problems a month or two ago. Turf that is shaded in the fall is weaker entering winter, essentially guaranteeing that it also will emerge from winter in a weakened state.

The putting green by #1 tee has several issues, including its size and drainage problems. However, one of the greatest challenges this green faces is the growing environment. The picture below was taken on Monday, November 9, a full six weeks before the winter solstice:

With 2/3 to 3/4 of the green in the shade, you might think this picture was taken in early morning or late afternoon. The unfortunate truth is that it was taken at 12:30 PM. Last winter was tough on all of the grass, but we had only one green which actually suffered turf loss and had to be reseeded: The putting green.

Saturday, November 7, 2015

Locating the Leak

We have a saying that irrigation leaks will always show themselves in due time. Therefore it was quite a mystery when the pump station by #5 green began cycling frequently to maintain pressure, yet no leak could be found.

Based on the amount of water we were losing, we knew that there was exactly one gallon per minute flowing...someplace. With 25 miles of pipe in the ground, that may not sound like a whole lot of water loss, but it equals over 1,400 gallons per day--something we'd expect to find pretty quickly.

After isolating various sections of the system we were able to narrow the source of the leak to the irrigation loop around #5 green. Now we only had a few hundred feet of pipe to check, but once again, still couldn't see any water bubbling to the surface, or turf that felt like quicksand.

At this point, we speculated that water could be making its way back into the lake, however with the green surrounded on three sides by water, the question of how to determine the exact location still had us scratching our heads. The thought of using an indicator dye occurred to us, but we needed to get the dye just into the greens loop, and not the miles of pipe which the pump station supplies.

The solution was to use the quick coupling valves we typically hook into when handwatering the greens. We shut the isolation valve to #5 green, relieved the water pressure, hooked a portable air tank to a quick coupler to remove water, poured some dye into a second quick coupler, then opened the isolation valve and re-pressurized the green's irrigation loop.

Within an hour, we had our answer, and the mystery of where the water was going had been solved. Sure enough, the point of least resistance for the leaking water was not coming to the surface of the ground as we typically see. Instead it was making its way into a drain line near the front of the green, which exits into the lake.

The 2" PVC irrigation pipe and corrugated 4" drain line run perpendicular to each other, so the place to start digging was where the two pipes cross each other.

When the pipe crossing area was exposed, it was easy to see why the water never made it to the surface, as the perforated drain line and surrounding pea gravel took this water straight to the lake.

The actual source of the leak was a glue fitting which had gone bad after 25+ years. All in all, a relatively simple fix--once we knew where to dig.

Based on the amount of water we were losing, we knew that there was exactly one gallon per minute flowing...someplace. With 25 miles of pipe in the ground, that may not sound like a whole lot of water loss, but it equals over 1,400 gallons per day--something we'd expect to find pretty quickly.

After isolating various sections of the system we were able to narrow the source of the leak to the irrigation loop around #5 green. Now we only had a few hundred feet of pipe to check, but once again, still couldn't see any water bubbling to the surface, or turf that felt like quicksand.

|

| A green surrounded by water made locating the leak difficult. |

At this point, we speculated that water could be making its way back into the lake, however with the green surrounded on three sides by water, the question of how to determine the exact location still had us scratching our heads. The thought of using an indicator dye occurred to us, but we needed to get the dye just into the greens loop, and not the miles of pipe which the pump station supplies.

The solution was to use the quick coupling valves we typically hook into when handwatering the greens. We shut the isolation valve to #5 green, relieved the water pressure, hooked a portable air tank to a quick coupler to remove water, poured some dye into a second quick coupler, then opened the isolation valve and re-pressurized the green's irrigation loop.

|

| The tools used to get dye into the irrigation loop at #5 green. |

|

| The dye seeps into the lake from the drain line. |

|

| The completed repair. |

The actual source of the leak was a glue fitting which had gone bad after 25+ years. All in all, a relatively simple fix--once we knew where to dig.

Friday, October 30, 2015

Getting Geese to Go

With 16 ponds and 40 acres of wetlands on Club property, the potential for geese to quickly become a big, messy problem is always on our minds. Preventing this is an ongoing battle, and requires a multipronged attack.

The measures we use to discourage geese from calling Laurel Creek home include noise makers, stringing wire across the lakes, egg addling, and the stare down from pooches Buster and Thor. While these tactics get most geese to quickly take flight, there always seem to be a few stubborn ones that just don't want to leave.

Thankfully, we acquired a new piece of equipment this year which has proven to be very effective in getting the geese to go--a laser pointer.

To be clear, this isn't the kind of pointer you'd use for your Powerpoint presentation. No, this is a powerful beam which can even be used during daylight. As the photo shows, the laser can easily be seen across the lake on the rocks behind #5 green. Focusing this on geese quickly makes them nervous, and off they go.

The measures we use to discourage geese from calling Laurel Creek home include noise makers, stringing wire across the lakes, egg addling, and the stare down from pooches Buster and Thor. While these tactics get most geese to quickly take flight, there always seem to be a few stubborn ones that just don't want to leave.

Thankfully, we acquired a new piece of equipment this year which has proven to be very effective in getting the geese to go--a laser pointer.

To be clear, this isn't the kind of pointer you'd use for your Powerpoint presentation. No, this is a powerful beam which can even be used during daylight. As the photo shows, the laser can easily be seen across the lake on the rocks behind #5 green. Focusing this on geese quickly makes them nervous, and off they go.

Sunday, October 25, 2015

That's some fine Fine Fescue

The goal in the Fescue areas of the golf course is to create a sward which is penal, yet allows the ball to be found and advanced. While this sounds simple enough, achieving this is anything but easy for a number of reasons.

One of the more common issues we deal with is the Fescue receiving unwanted inputs, such as irrigation water. The tee irrigation which was installed a few years ago has at least allowed us to target the tee boxes, and not unnecessarily throw water into the Fescue. While the extremely dry parts of August and September presented many challenges on the golf course, it did benefit the Fescue. With no rainfall, there was a dramatic difference between Fescue which received irrigation and that which did not.

The picture below was taken from #9 tee. In the foreground, adjacent to the tee, you can see lush, green, and very thick Fescue. However, as you look toward the fairway, there was quite a dramatic difference:

A closer look at an unirrigated area of Fescue shows this more clearly:

Aesthetically, the Fescue may have been past its prime, as seedheads had already broken off. However, from a playability standpoint, it was at its peak--a ball landing here could easily be found and advanced.

One of the more common issues we deal with is the Fescue receiving unwanted inputs, such as irrigation water. The tee irrigation which was installed a few years ago has at least allowed us to target the tee boxes, and not unnecessarily throw water into the Fescue. While the extremely dry parts of August and September presented many challenges on the golf course, it did benefit the Fescue. With no rainfall, there was a dramatic difference between Fescue which received irrigation and that which did not.

The picture below was taken from #9 tee. In the foreground, adjacent to the tee, you can see lush, green, and very thick Fescue. However, as you look toward the fairway, there was quite a dramatic difference:

A closer look at an unirrigated area of Fescue shows this more clearly:

Aesthetically, the Fescue may have been past its prime, as seedheads had already broken off. However, from a playability standpoint, it was at its peak--a ball landing here could easily be found and advanced.

Friday, October 16, 2015

Never a Dull Moment

It appeared to be bad news, as one of our pump station's pressure maintenance pump was producing a very low volume of water. With the station isolated from the golf course, the 5 horsepower motor should be doing much better than this trickle:

One of the challenges in determining the cause of the problem is that the pressure maintenance pump and its submersible motor are both located beneath the pump station skid in the concrete vault known as a wet well.

From ground level, this is what the pump station skid looks like:

Peering in the access hatch on the right side of the skid, you can see that the two main pump discharge pipes are on the sides, with the smaller pressure maintenance discharge pipe and its electrical supply conduit located between them.

It looked like we were going to have to have a service truck come in and pull the steel discharge pipe, pressure maintenance pump and motor up out of the wet well--not a quick, easy, or inexpensive solution.

However, before going that route it seemed like a reasonably nice day for a dip. So, into the wet well I went, and for my efforts, the treasure I was rewarded with was...a plastic shopping bag wrapped around the pump's impeller. Not sure how it got there, but that's the kind of quick fix, we'll happily take.

Now this flow looks much better:

One of the challenges in determining the cause of the problem is that the pressure maintenance pump and its submersible motor are both located beneath the pump station skid in the concrete vault known as a wet well.

From ground level, this is what the pump station skid looks like:

Peering in the access hatch on the right side of the skid, you can see that the two main pump discharge pipes are on the sides, with the smaller pressure maintenance discharge pipe and its electrical supply conduit located between them.

It looked like we were going to have to have a service truck come in and pull the steel discharge pipe, pressure maintenance pump and motor up out of the wet well--not a quick, easy, or inexpensive solution.

However, before going that route it seemed like a reasonably nice day for a dip. So, into the wet well I went, and for my efforts, the treasure I was rewarded with was...a plastic shopping bag wrapped around the pump's impeller. Not sure how it got there, but that's the kind of quick fix, we'll happily take.

Now this flow looks much better:

Friday, October 9, 2015

Dead or Dormant?

Every year we hear people refer to their unirrigated lawns as "dead" in the summer. With a very hot, dry August and September, this year was no exception. The area behind #1 green was definitely looking crispy in mid-September. But was this grass dead or just dormant?

Well, if you look at this same area today, low and behold the grass has magically come back to life.

So what was done here to cause such a remarkable improvement--aerification, seed, fertilizer? No, just some much needed rainfall and cooler temperatures were all it took to get this turf back in decent shape. Next summer, try to remember, it's not dead, just dormant.

Well, if you look at this same area today, low and behold the grass has magically come back to life.

So what was done here to cause such a remarkable improvement--aerification, seed, fertilizer? No, just some much needed rainfall and cooler temperatures were all it took to get this turf back in decent shape. Next summer, try to remember, it's not dead, just dormant.

Monday, October 5, 2015

Cut While You Can

Once again, we should be careful what we wish for. Following a very dry August and September, some steady rainfall was welcomed. However, after five days in a row with precipitation, totaling 5.25", enough is enough.

This time of year we are typically mowing greens every day, and fairways three times per week. Non-stop rain can lead to some tough choices: Should we cut wet turf and risk mechanical damage, or not cut and deal with potential scalping by removing too much leaf tissue when we can finally get the mowers out?

Fortunately, with well-draining, sand-based greens, we were able to find a break between showers and still get the greens cut every day last week. The fairways, on the other hand, went from Thursday until Monday without being cut.

Four days between mowings on fairways can be a problem. However, prior to last week's rain, we made a pretty heavy application of plant growth regulator on the fairways to slow growth. Between this, and some very cool nights, growth was slowed, and we didn't have to deal with "baling hay" this time.

This time of year we are typically mowing greens every day, and fairways three times per week. Non-stop rain can lead to some tough choices: Should we cut wet turf and risk mechanical damage, or not cut and deal with potential scalping by removing too much leaf tissue when we can finally get the mowers out?

|

| Definitely no fairway mowing could be done on Friday. |

Fortunately, with well-draining, sand-based greens, we were able to find a break between showers and still get the greens cut every day last week. The fairways, on the other hand, went from Thursday until Monday without being cut.

Four days between mowings on fairways can be a problem. However, prior to last week's rain, we made a pretty heavy application of plant growth regulator on the fairways to slow growth. Between this, and some very cool nights, growth was slowed, and we didn't have to deal with "baling hay" this time.

Friday, September 25, 2015

The Dark and the Light

For those who work on the golf course maintenance staff, the hours can be long and tiring. To stay ahead of play we start before first light each morning.

In an effort to help the crew do their job safely when it's still dark out, we made a recent purchase.

While rising before the rooster may not always be the most fun, there are many aspects of the job that are rewarding and make it all worthwhile. Witnessing scenes like this is a privilege we never take for granted.

In an effort to help the crew do their job safely when it's still dark out, we made a recent purchase.

While rising before the rooster may not always be the most fun, there are many aspects of the job that are rewarding and make it all worthwhile. Witnessing scenes like this is a privilege we never take for granted.

Monday, September 21, 2015

Weary of Weevils

Over the past several years, the Annual Bluegrass Weevil has become the toughest insect we have to battle on the golf course. With a high percentage of Poa on the greens, we are constantly monitoring for weevils, particularly in the collars. There are a number of generations of weevils throughout the growing season, and it often feels as if the war on weevils will never end.

As the name implies, these weevils prefer Poa Annua over Bentgrass. However, as a person might prefer filet over hamburger, when there's nothing else to munch on, the weevils will cause damage to Bentgrass.

We've heard about this for some time, and have seen pictures of Bent injury, but this week was the first time we've experienced it at Laurel Creek. With little Poa in the fairways, they have gone after Bentgrass.

While the turf in the picture below may not exactly look devastated, close inspection of the flagged mound shows signs of thinning.

Digging into the turf, the cause of the trouble is found--weevil larvae.

As the name implies, these weevils prefer Poa Annua over Bentgrass. However, as a person might prefer filet over hamburger, when there's nothing else to munch on, the weevils will cause damage to Bentgrass.

We've heard about this for some time, and have seen pictures of Bent injury, but this week was the first time we've experienced it at Laurel Creek. With little Poa in the fairways, they have gone after Bentgrass.

While the turf in the picture below may not exactly look devastated, close inspection of the flagged mound shows signs of thinning.

Digging into the turf, the cause of the trouble is found--weevil larvae.

We pulled several plugs and placed them in a salt solution, causing the larvae to leave the turf and float to the surface. This area had close to 100 larvae per square foot. Bentgrass is much more tolerant of weevil activity than Poa, and we certainly don't anticipate any widespread damage at this time of the year. However, going forward, we know we'll have to keep a watchful eye on the tees and fairways for wicked weevils.

Saturday, September 12, 2015

Holy Hydrophobic!

It often surprises people to see us hand watering following a rain event. Last Thursday, after three plus weeks of no precipitation, we received 1.75" of rain over a 24 hour period. Unlike thunderstorms, where much of the water runs off, you might think that Thursday's slow rain would have evenly soaked the soil profile.

However, after this extended dry period, areas often become hydrophobic. Literally, this means water-fearing. But in turf terms, when we say hydrophobic, we are referring to soils which are water repellent. If you've ever let a house plant dry too much, you've likely witnessed water running off, instead of soaking in.

The picture below is from #7 approach after Thursday's rain. That is still some very hard, dry, crumbly soil!

The next time you see us watering after rain, you'll know why.

However, after this extended dry period, areas often become hydrophobic. Literally, this means water-fearing. But in turf terms, when we say hydrophobic, we are referring to soils which are water repellent. If you've ever let a house plant dry too much, you've likely witnessed water running off, instead of soaking in.

The picture below is from #7 approach after Thursday's rain. That is still some very hard, dry, crumbly soil!

The next time you see us watering after rain, you'll know why.

Monday, September 7, 2015

Still Hot and Dry

The timing of our late summer aerification typically coincides with a shift in the weather, going from hot, dry summertime conditions, to cooler temperatures and beneficial rainfall. Clearly, somebody forgot to make Mother Nature aware of this, as she has yet to turn the page.

We have always said that it takes one good rainfall to help the course completely heal from aerification. Unfortunately, that didn't happen this year. As of last Wednesday, we were over 3.5" behind in precipitation for the past 60 days. Given this lack of rain, we have relied almost exclusively on the irrigation system to provide the water the "patient" requires following major surgery. Over 800 man hours have been dedicated to hand watering fairways this season, as a supplement to the irrigation system sprinklers. Yet, with no rain, it's been a battle trying to maintain moisture at a uniform level, which will help the turf recover most quickly.

The second blow from this one-two punch has been the excessive heat. Last week, we enjoyed heat wave number five, and this week we may be dealing with number six. For the first time in 42 years, September started with four days in the 90s. Again, this has proved to slow recovery from aerification and lead us to irrigate more than we typically would under normal growing conditions this time of year.

With cooler temperatures and timely rainfall, late summer and early fall often allow us to provide some of the best playing conditions of the year--firm and fast. Undoubtedly, we will get there...just not as quickly as we'd like.

We have always said that it takes one good rainfall to help the course completely heal from aerification. Unfortunately, that didn't happen this year. As of last Wednesday, we were over 3.5" behind in precipitation for the past 60 days. Given this lack of rain, we have relied almost exclusively on the irrigation system to provide the water the "patient" requires following major surgery. Over 800 man hours have been dedicated to hand watering fairways this season, as a supplement to the irrigation system sprinklers. Yet, with no rain, it's been a battle trying to maintain moisture at a uniform level, which will help the turf recover most quickly.

|

| An unirrigated section of the course. |

The second blow from this one-two punch has been the excessive heat. Last week, we enjoyed heat wave number five, and this week we may be dealing with number six. For the first time in 42 years, September started with four days in the 90s. Again, this has proved to slow recovery from aerification and lead us to irrigate more than we typically would under normal growing conditions this time of year.

|

| Our on site weather station's recording last Wednesday. |

With cooler temperatures and timely rainfall, late summer and early fall often allow us to provide some of the best playing conditions of the year--firm and fast. Undoubtedly, we will get there...just not as quickly as we'd like.

Friday, August 28, 2015

Only at a Major

The behind the scenes work for one of golf's major championships never ceases to amaze. There are more individuals working in and around this one bunker than most golf courses have on their entire greens staff:

And while this may look like a time lapse of a single mower at the US Open, it is not. Fairways get cut pretty quickly when you send out 17 mowers at once:

And while this may look like a time lapse of a single mower at the US Open, it is not. Fairways get cut pretty quickly when you send out 17 mowers at once:

Saturday, August 15, 2015

Ready to Roll

After aerifying the greens on Monday, we applied over 75 tons of sand to fill the holes. With all of this sand, we typically aren't able to mow the greens for a few days. However, we will begin rolling them the day after we aerify.

In the past, this rolling ahead of golfers could be a messy experience, as the sand would stick to the roller, then drop off leaving clumps across the green. We'd often have to have two employees follow the roller using dew whips or blowers to disperse the sand.

A less messy alternative is waiting until the greens are completely dry to roll them. However, if there's a heavy dew, that can mean not starting to roll until 10:00 in the morning, causing us to interfere with play.

Fortunately, several years ago, we found a solution to this issue. We head out with the roller first thing in the morning, but run the green sprinklers for three minutes (or one spin), just ahead of the roller. You might expect that adding moisture to the surface would lead to more sand sticking, but it actually does the opposite. If we time it right, and start rolling as soon as the heads drop, there is virtually no sand pick up and no clumps to deal with.

In the past, this rolling ahead of golfers could be a messy experience, as the sand would stick to the roller, then drop off leaving clumps across the green. We'd often have to have two employees follow the roller using dew whips or blowers to disperse the sand.

A less messy alternative is waiting until the greens are completely dry to roll them. However, if there's a heavy dew, that can mean not starting to roll until 10:00 in the morning, causing us to interfere with play.

Fortunately, several years ago, we found a solution to this issue. We head out with the roller first thing in the morning, but run the green sprinklers for three minutes (or one spin), just ahead of the roller. You might expect that adding moisture to the surface would lead to more sand sticking, but it actually does the opposite. If we time it right, and start rolling as soon as the heads drop, there is virtually no sand pick up and no clumps to deal with.

|

| The roller is waiting for the sprinklers to shut down. |

Saturday, August 8, 2015

Sometimes softer in summer?

It may seem counterintuitive that golf course conditions may not be as firm during periods of hot, dry summer weather, as they are during cooler periods when we receive more consistent rainfall. However, there are several reasons why this may occur, most of which involve the irrigation system, and the frequency and scheduling of irrigation cycles:

- Let's start with the irrigation system itself. Our system was designed in the 1980s and doesn't provide the uniformity of coverage of a more modern design. Despite having employees spend up to 500 man hours per month hand watering to supplement coverage deficiencies, we still can't provide the uniformity of rainfall. Thus, at times, it feels like Goldilocks--this area is too wet, this area is too dry, this area is just right.

- Given the hit or miss nature of rain events in the summer, there are occasionally times when we schedule an irrigation cycle, not willing to take the risk that we "might" get a shower or thunderstorm. For example, last Friday was forecast to be a washout with temperatures staying in the 70s...then they called for showers...followed by a change to rain from the city south. And how did the day actually turnout? Brilliant sunshine and low humidity with a high of 85. A day that was expected to add moisture to the soil profile, instead ended up lowering moisture levels. We are fortunate to have an on-site weather station and the ability to remotely initiate or suspend irrigation cycles, but it's easy to feel like you need a crystal ball to accurately know the upcoming weather and schedule the irrigation accordingly.

|

| Friday's weather surprised many. |

- With cool season turf, the longest root system of the year is in the spring. With less stressful environmental conditions, and plenty of roots to bring moisture and nutrients into the plant, going long periods between rain or irrigation isn't a problem at that time of year. However, as you can see below, in August, cool season grass has the shortest roots of the entire year. In the case of Poa greens the "functional root sytem" this time of year may be less than one inch in length. Allowing the soil to dry beyond a point where the roots can access moisture, can quickly spell trouble.

|

| The shortest roots of the year are in August. |

- The greens are designed to drain well, and the Dryject treatment they received in the spring has increased the water infiltration rate. The data for the graph below comes from one of the sensors buried in #1 green. The spike in moisture seen in the orange line was caused by a fairly significant rain event of .70". However, within 24 hours after the rain, moisture levels at a 2" and 7" depth in the green are very close to the pre-rain numbers. In this situation, the rain didn't provide a reservoir of moisture which the turf can draw from for several days, and irrigation may be required.

- Finally, as we enter August and get ready for aerification, we need to be sure we have good, uniform soil moisture. Similar to surgery on a person, aerifying has long-term health benefits for the turf, but it also causes some temporary stress. We need to have a healthy "patient" in order to minimize the risk of post-surgical complications (like wilt), and help speed recovery.

Monday, August 3, 2015

Time to Tine

We will begin aerification next Monday, and are hoping that things cool off a bit so we can get the greens aerified first, followed by tees and fairways.

While aerification most certainly has long-term health benefits for the plant, the process of coring, dragging, topdressing, and working the sand into the holes of the green can be stressful. Fortunately, the long-range forecast looks like we'll break this extended heat wave and get back to some temperatures which are more tolerable for both humans and turf.

While aerification most certainly has long-term health benefits for the plant, the process of coring, dragging, topdressing, and working the sand into the holes of the green can be stressful. Fortunately, the long-range forecast looks like we'll break this extended heat wave and get back to some temperatures which are more tolerable for both humans and turf.

Monday, July 27, 2015

One Step at a Time

New steps, which match the retaining wall, are going to be installed from the upper practice tee to the lower tee.

The installation of these steps will begin next week and may take the contractor a few days to complete. Therefore, we removed one set of wooden steps, giving the contractor a place to start. Once they are completed and put into service, we will remove the second set of wooden steps.

The installation of these steps will begin next week and may take the contractor a few days to complete. Therefore, we removed one set of wooden steps, giving the contractor a place to start. Once they are completed and put into service, we will remove the second set of wooden steps.

Friday, July 17, 2015

A Great Team

Every year it can be a challenge to fill the ranks of our course care team. We have been very fortunate this year to have a great group of guys who are hard-working, conscientious, and strive to produce outstanding playing conditions for you every day.

Often they work behind the scenes, however if you happen to run into any of the crew, feel free to give them a thumbs up for their hard work.

Often they work behind the scenes, however if you happen to run into any of the crew, feel free to give them a thumbs up for their hard work.

|

| Prepping #7 green for the Men's Club Championship. |

Monday, July 13, 2015

A Good Test for the Bunkers

Last Thursday night, the golf course endured quite a storm. Nearly 1.5" of rain came down in a short period, making a mess of the bunkers.

While many of the bunkers had washouts, sand contamination, and puddles, there were some notable exceptions. The asphalt lined, Matrix bunkers performed flawlessly. The pictures below of #7 and #10 are how we found the bunkers when we arrived Friday morning. What a difference!

While many of the bunkers had washouts, sand contamination, and puddles, there were some notable exceptions. The asphalt lined, Matrix bunkers performed flawlessly. The pictures below of #7 and #10 are how we found the bunkers when we arrived Friday morning. What a difference!

Monday, July 6, 2015

A New Approach

As part of the long-term goal of firming approaches, we have started an aggressive aerification and topdressing program. In order to achieve improvements as quickly as possible, we will be punching some holes and applying sand at least four times this year.

|

| Sand on #15 approach, prior to being broomed in. |

Monday, June 29, 2015

Stop Right There!

While the golf course greens are dominated by Poa Annua, we have been able to keep the fairways virtually 100% Bentgrass for over 25 years through the use of a selective post-emergent herbicide (which is not labeled for use on putting greens).

This year we are using an aggressive plant growth regulator (PGR) on the fairways, which gives Bentgrass a competitive edge over Poa. This is a different product than the PGR we use on the greens.

In the interface where the greens and fairways meet, we may experience some overlap of fairway and green spray applications. As you can see in the picture below, the Poa is not a fan of this combination, and will not be able to expand outward from the green complex.

This year we are using an aggressive plant growth regulator (PGR) on the fairways, which gives Bentgrass a competitive edge over Poa. This is a different product than the PGR we use on the greens.

In the interface where the greens and fairways meet, we may experience some overlap of fairway and green spray applications. As you can see in the picture below, the Poa is not a fan of this combination, and will not be able to expand outward from the green complex.

|

| Weakened Poa can be seen in yellow patches. |

Tuesday, June 23, 2015

Average?

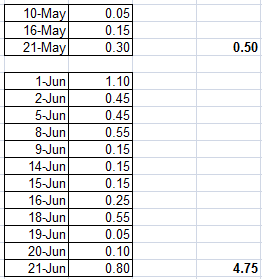

When all is said and done, 2015 may end up being an "average year" in terms of weather. However, it definitely feels like a rollercoaster ride both in terms of temperatures and precipitation thus far. A quick look at rainfall totals for all of May, and the first three weeks of June, illustrate this:

With a full week left this month, we've already received 4.75 " of rain--that's close to 10X the precipitation we got in all of May. Dramatic changes like this keep us on our toes, as we have to quickly shift from one type of activity (such as hand watering), to another (such as bunker pumping).

With a full week left this month, we've already received 4.75 " of rain--that's close to 10X the precipitation we got in all of May. Dramatic changes like this keep us on our toes, as we have to quickly shift from one type of activity (such as hand watering), to another (such as bunker pumping).

Monday, June 15, 2015

Welcoming Weevils?

For many years we have applied a selective post-emergent herbicide in late fall for the control of Poa Annua on the tees and fairways. The product has a reputation for being most effective when the weather's bad--basically, the worse the winter, the better this works. Therefore, given how harsh this past winter was, it was somewhat surprising to find more Poa in the fairways this spring than we've seen in the past.

There are a few options for controlling Poa in fairways, including the use of other selective herbicides, or plant growth regulators. But what about trying a biological control?

One of the biggest insect concerns on golf courses in the northeast is the Annual Bluegrass Weevil. With Poa (Annual Bluegrass) being the predominant turf species on the greens, we must guard against this damaging insect. However, on fairways we may welcome weevils as they can potentially help keep the fairways clean of Poa.

Here's the plan: We spray plant protectants on the greens to prevent weevil damage and do not treat the fairways, allowing the weevils to selectively remove the small amount of Poa we have.

Well, that sure sounds simple and easy. Here's the catch--while Poa may be the preferred plant for weevils to wreak havoc upon, once the Poa is gone, they don't hop on the bus and head to the course down the street. So, despite their name, Annual Bluegrass Weevils can damage Creeping Bentgrass.

Thus the plan becomes a bit more complex: Allow weevils to munch on fairway Poa, but don't let them get so out of control that they start damaging the Bent.

In order to do this, we have allowed weevils to work on the Poa in fairways throughout the spring. The damage to the small amount of Poa we have has been welcomed.

However, now that we're in the summer heat, we don't want weevils adding to the stresses that the Bent turf goes through. We will now apply a plant protectant to the fairways in order to keep the weevils from working their magic on the Bentgrass.

As the year progresses we'll see if allowing this limited weevil activity truly helped keep Poa out of the fairways, while protecting Creeping Bentgrass.

There are a few options for controlling Poa in fairways, including the use of other selective herbicides, or plant growth regulators. But what about trying a biological control?

One of the biggest insect concerns on golf courses in the northeast is the Annual Bluegrass Weevil. With Poa (Annual Bluegrass) being the predominant turf species on the greens, we must guard against this damaging insect. However, on fairways we may welcome weevils as they can potentially help keep the fairways clean of Poa.

|

| Weevils have damaged the Poa in the fairway. |

Well, that sure sounds simple and easy. Here's the catch--while Poa may be the preferred plant for weevils to wreak havoc upon, once the Poa is gone, they don't hop on the bus and head to the course down the street. So, despite their name, Annual Bluegrass Weevils can damage Creeping Bentgrass.

Thus the plan becomes a bit more complex: Allow weevils to munch on fairway Poa, but don't let them get so out of control that they start damaging the Bent.

In order to do this, we have allowed weevils to work on the Poa in fairways throughout the spring. The damage to the small amount of Poa we have has been welcomed.

However, now that we're in the summer heat, we don't want weevils adding to the stresses that the Bent turf goes through. We will now apply a plant protectant to the fairways in order to keep the weevils from working their magic on the Bentgrass.

As the year progresses we'll see if allowing this limited weevil activity truly helped keep Poa out of the fairways, while protecting Creeping Bentgrass.

|

| At only 1/8" in length, the weevil larvae resemble a grain of rice. |

Subscribe to:

Comments (Atom)